I-DG CBK othomathikhi yokuphinda usebenzise kabusha imishini

I-CBK-2157-3T

Isingeniso Sokuvuselelwa Kwemishini Yokuvuselelwa Kwamanzi

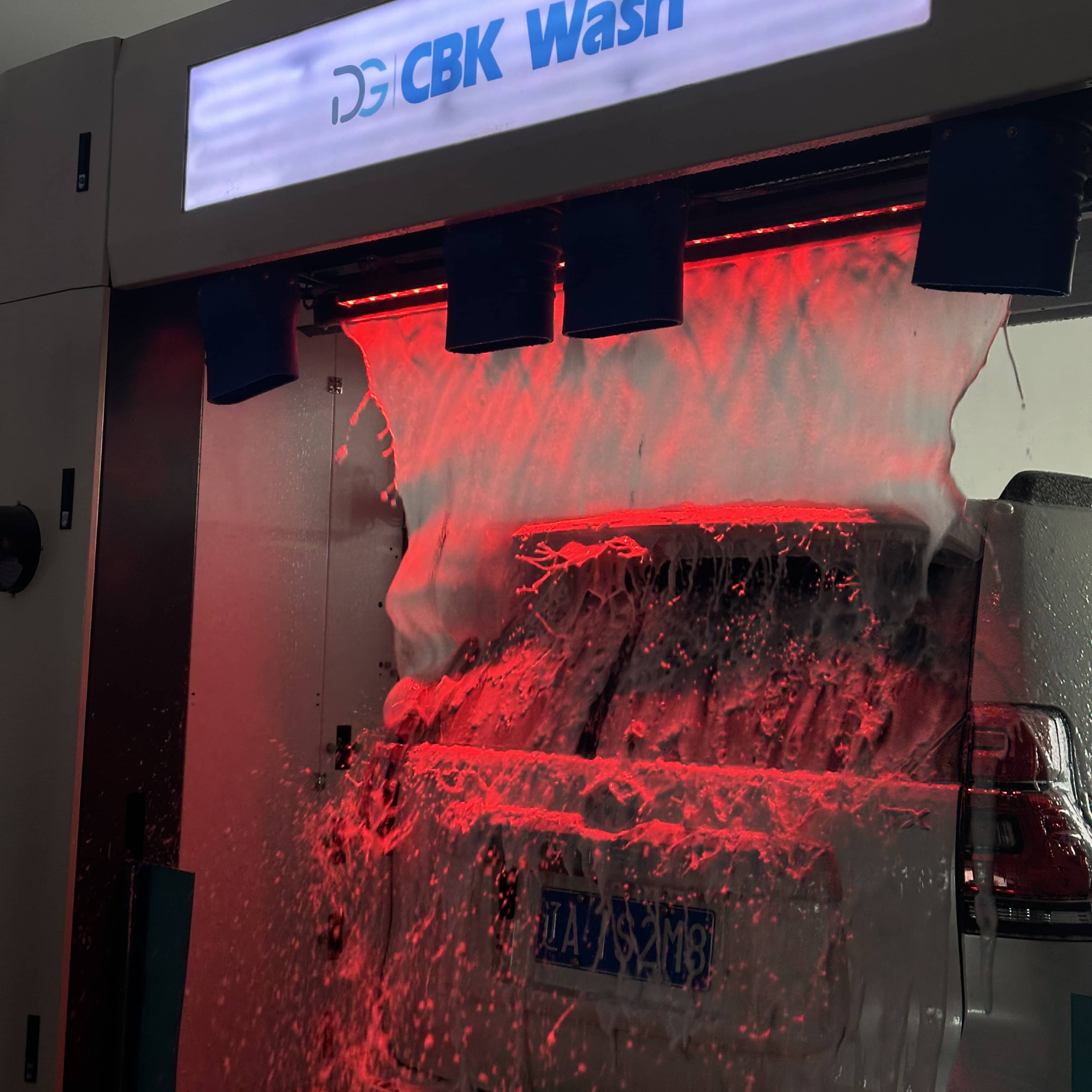

Ukuboniswa Komkhiqizo

Mina. Ukuchazwa Komkhiqizo

a) ukusetshenziswa okuyinhloko

Umkhiqizo osetshenziselwa ukukholwa kwendle yemoto evuselelwe kabusha.

b) Izici zomkhiqizo

1. Isakhiwo esihlangene kanye nokusebenza okuthembekile

Adopt I-Stainless Box Box PackAging Hlela, enhle futhi eqinile. Ukulawula okuqondayo kakhulu, ukusebenza kwesimo sezulu sonke esingenamkhawulo, nokuthembekile, futhi kuxazululwe ukusebenza okungajwayelekile kwemishini okubangelwa ukwehluleka kwamandla.

2. Umsebenzi wezandla

Inomsebenzi wamathangi esihlabathi acwebezelayo ngesandla namathangi e-carbon, futhi ubona ukugcwala okuzenzakalelayo ngokungenela komuntu.

3. Umsebenzi othomathikhi

Umsebenzi ozenzakalelayo wokusebenza kwemishini, uqaphela ukuphathwa okugcwele okuzenzakalelayo kwemishini, zonke izimo sezulu ezinganakekelwa futhi zihlakaniphe kakhulu.

4. Misa (Break) Ukuvikelwa Kogesi Kagesi

Amasethi amaningi amamojula kagesi anomsebenzi wesitoreji sepharamitha asetshenziswa ngaphakathi kwemishini ukugwema ukusebenza okungajwayelekile kwemishini ebangelwa ukwehluleka kwamandla okubangelwa ukwehluleka kwamandla.

I-5. Ipharamitha ngalinye lingashintshwa njengoba kudingeka

Ipharamitha ngayinye ingashintshwa njengoba kudingeka ngokuya ngekhwalithi yamanzi nokusetshenziswa kokucushwa, amapharamitha angashintshwa, futhi isimo esisebenzayo semikhiqizo ye-Equipment Energy singashintshwa ukuze kufinyelelwe umphumela omuhle kakhulu wekhwalithi yamanzi.

c) Imibandela Yokusebenzisa

Izimo eziyisisekelo zokusetshenziswa kwemishini yokwelashwa kwamanzi okuzenzakalelayo:

| Into yendaba | Okudingekayo | |

| Izimo zokusebenza | Ukuxineka komsebenzi | 0.15 ~ 0.6MPA |

| Ukushisa kwamanzi okushisa amanzi | 5 ~ 50 ℃ | |

| Indawo Yomsebenzi | Ukushisa Kwemvelo | 5 ~ 50 ℃ |

| umswakama ohlobene | ≤60% (25 ℃) | |

| Ukunikezwa kwamandla kagesi | 220V / 380v 50hz | |

| Ikhwalithi Yamanzi Ekungeneni

| ukwebisile | ≤19FTU |

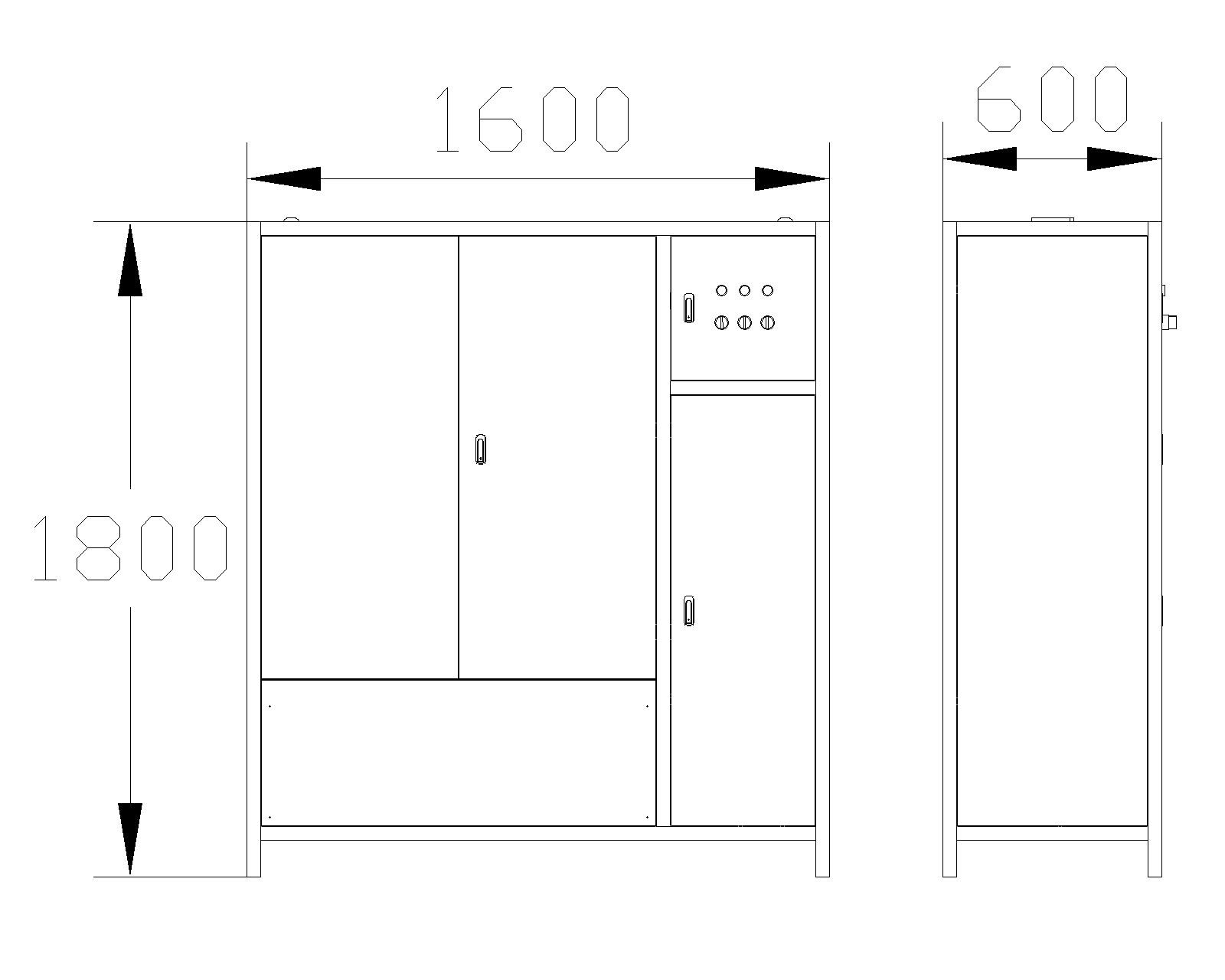

d) ubukhulu bangaphandle nepharamitha yezobuchwepheshe

II. Ukufakwa Komkhiqizo

a) Izinyathelo zokufakwa kokufakwa komkhiqizo

1. Qinisekisa ukuthi izidingo zokwakha eziyimali ahlangabezana nezidingo zokufakwa kwemishini.

2. Funda imiyalo yokufaka ngokucophelela futhi ulungiselele wonke amathuluzi nezinto zokwakha ezizofakwa.

I-3. Ukufakwa kwemishini nokuxhumeka kwesekethe kumele kugcwaliswe ngochwepheshe ukuze kuqinisekiswe ukusetshenziswa okujwayelekile kwemishini ngemuva kokufakwa.

I-4. Ukuphakelwa kuzosuselwa ku-inlet, okuphumayo nokuphuma, futhi kuzohambisana nokucaciswa kwamapayipi okufanele.

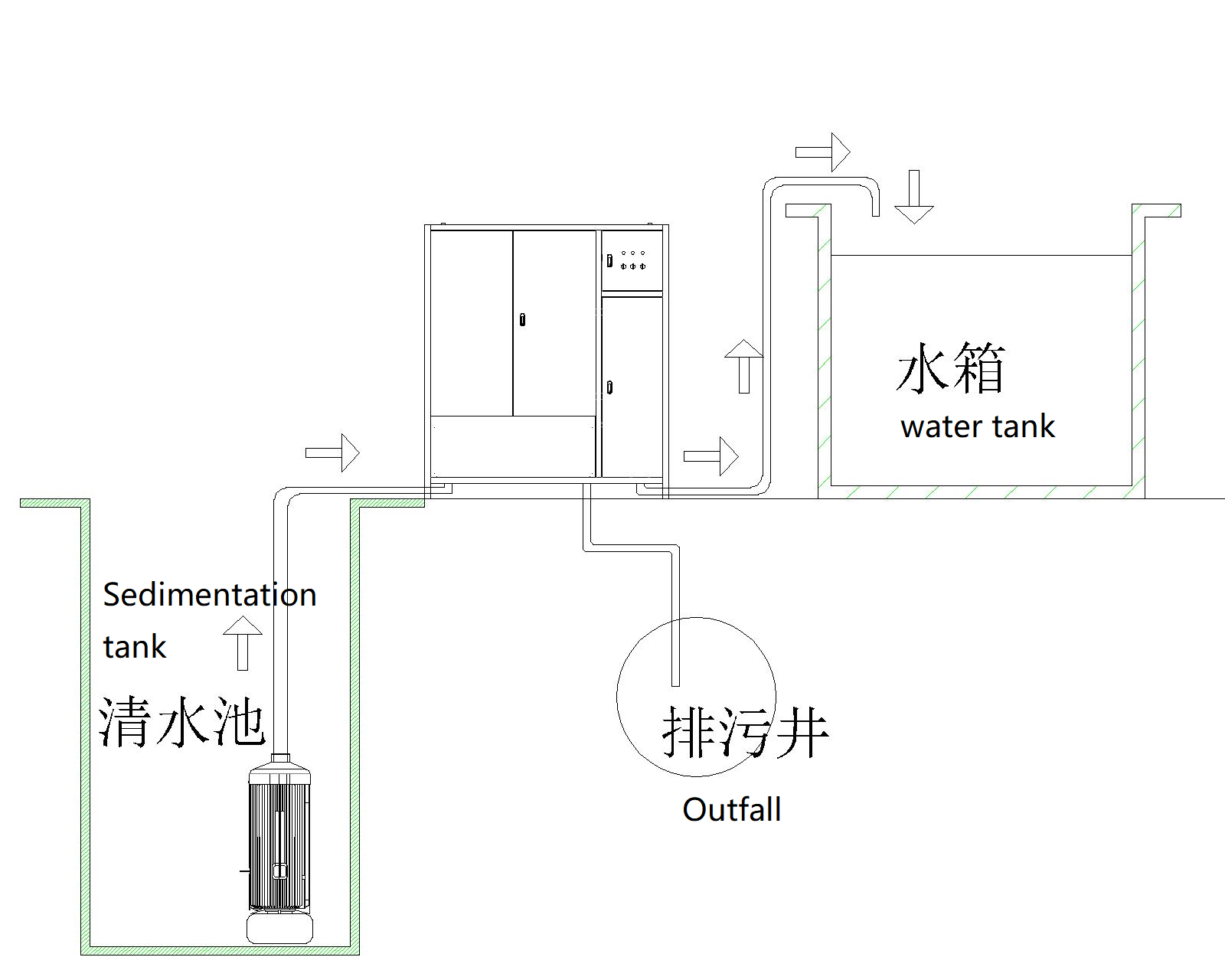

b) Indawo Yemishini

1. Lapho imishini ifakiwe futhi ihanjisiwe, kufanele isetshenziselwe ugqoko olungezansi kufanele lusetshenziselwe ukunyakaza, futhi ezinye izingxenye zivinjelwe njengamaphoyinti asekelayo.

2. Okufushane ibanga phakathi kwemishini kanye nokuphuma kwamanzi, okungcono, futhi ibanga phakathi kokuphuma kwamanzi kanye nesiteshi sokuthuthwa kwendle kufanele kugcinwe, ukuze kuvinjelwe umonakalo we-Siphon kanye nomonakalo we-sex. Shiya isikhala esithile sokulungiswa kwemishini nokulungisa.

3. Ungafaki imishini emvelweni ye-acid eqinile, i-alkali eqinile, amandla kazibuthe aqinile kanye nokudlidliza, ukuze ugweme ukulimaza uhlelo lokulawula ngogesi nokudala ukwehluleka kwemishini.

5

I-6. Ngokusemandleni ngangokunokwenzeka, faka imishini endaweni elahlekelwe yisikhathi esincane lapho kuvuthwa kwamanzi.

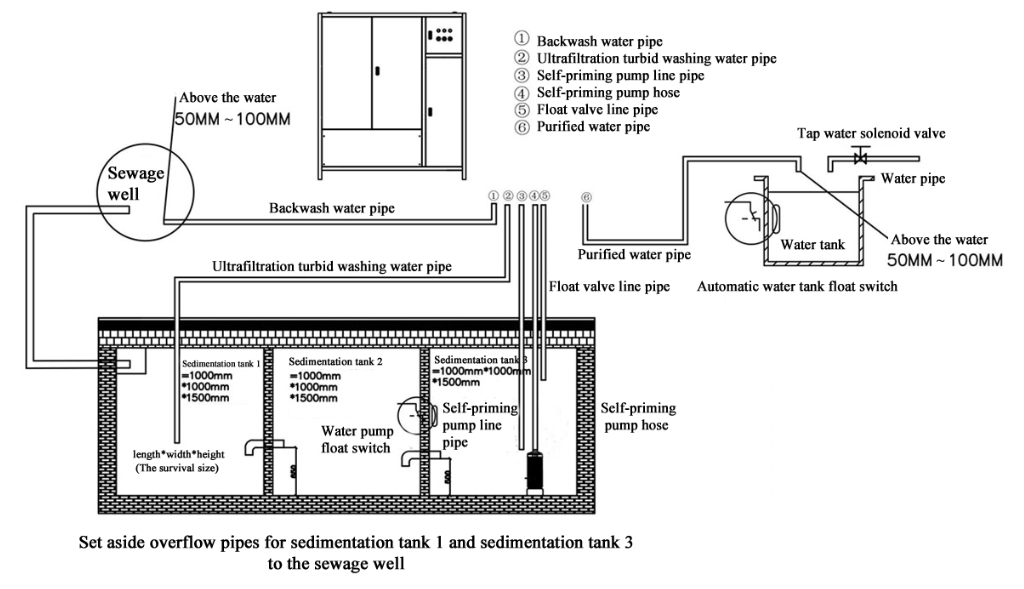

c) Ukufakwa kwamapayipi

1. Wonke amapayipi amanzi angamapayipi we-DN32PNC, amapayipi amanzi angama-200mm ngaphezulu komhlaba, ibanga ukusuka odongeni lingu-50mm, futhi ibanga lesikhungo sepayipi ngalinye lamanzi lingu-60mm.

2. Ibhakede kufanele lifakwe emanzini okugeza izimoto, futhi ipayipi lamanzi kampompi kufanele lengezwe ngenhla ibhakede. (Kunconywa ukufaka ibhakede eduze kwemishini yokwelashwa kwamanzi, ngoba ipayipi lamanzi emishini kudingeka lixhunywe ethangi lamanzi)

I-3. Ububanzi bawo wonke amapayipi agcwalisiwe yi-DN100mm, kanti ubude bepayipi bungu-100mm ~ 150mm ngaphesheya kodonga.

4

I-5. I-DN32 Wire

I-6.

7.

8. I-Sule Pool engenhla kufanele ibe nepayipi lamanzi, iyengeze ukulahlekelwa kwamanzi, ukugwema ukudala impompo engaphansi.

9. Isitolo samanzi kufanele sibe nebanga elithile ethangi lamanzi (cishe i-5cm) ukuvikela ukulimala kwe-Siphon futhi kubangele ukulimala kwemishini.

III. Izilungiselelo eziyisisekelo nemiyalo

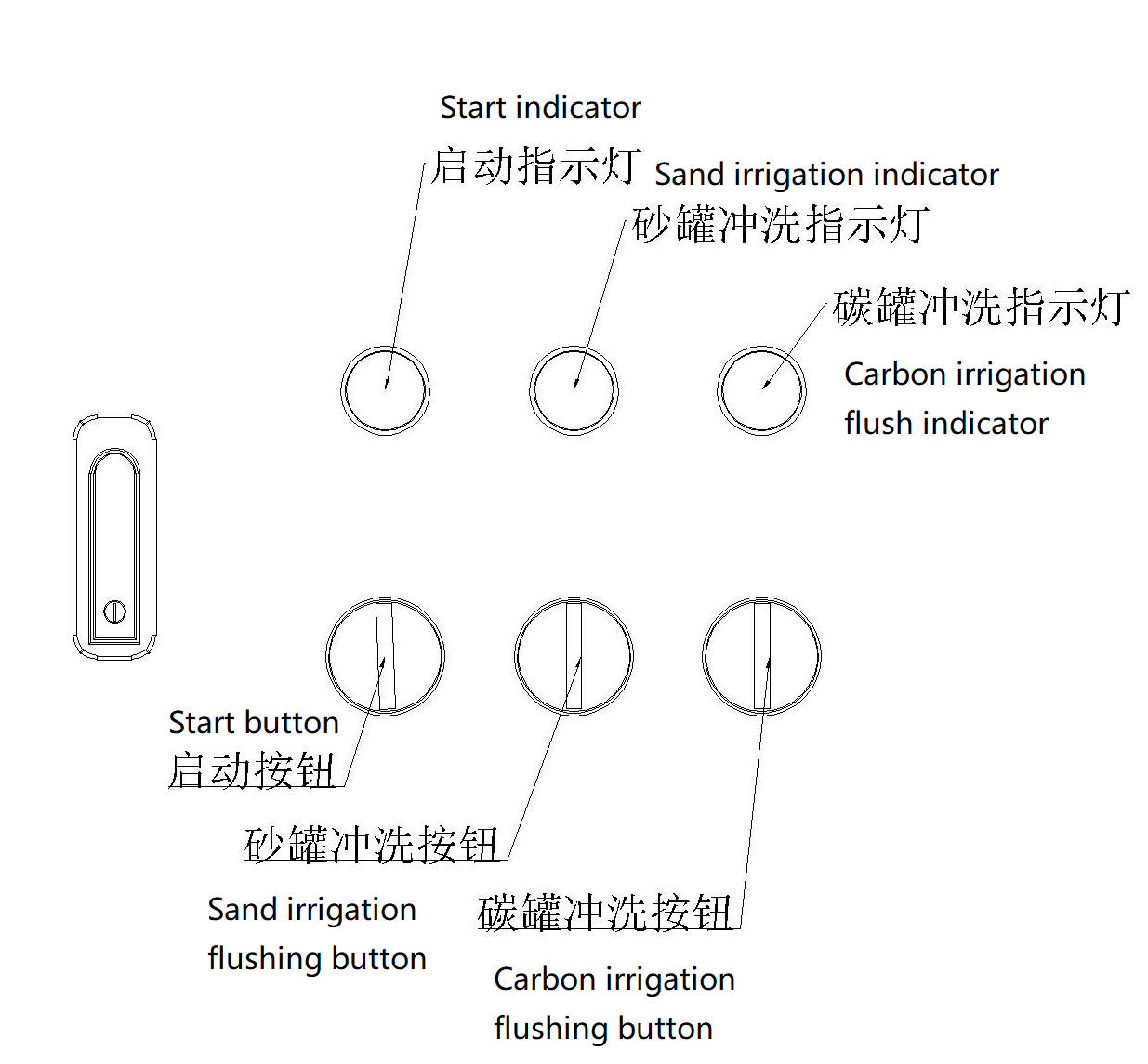

a) umsebenzi nokubaluleka kwephaneli yokulawula

b) Ukuhlelwa okuyisisekelo

1. Ifektri isetha isikhathi esisemuva sethangi lesihlabathi ukuze kube imizuzu eyi-15 nesikhathi sokugeza esihle sokuba imizuzu eyi-10.

2. Ifektri isetha i-carbon canister ye-backweshing isikhathi sokuba yimizuzu eyi-15 kanye nesikhathi sokugeza esihle sokuba imizuzu eyi-10.

3. Ifektri isethwe isikhathi esizenzakalelayo esishisayo singu-21: 00 PM, lapho imishini igcinwa khona inikwe amandla, ukuze umsebenzi wokuzenzakalelayo ozenzakalelayo ungaqalwa ngokujwayelekile ngenxa yokwehluleka kwamandla ngenxa yokwehluleka kwamandla.

4. Yonke le misebenzi engenhla yesikhathi Amaphoyinti wesikhathi angasetwa ngokuya ngezidingo zangempela zekhasimende, okungeyona imishini ezenzakalelayo ngokuphelele, futhi idinga ukugezwa ngesandla ngokwezidingo.

b) Ukuchazwa kwezilungiselelo eziyisisekelo

1. Bheka isimo esisebenzayo semishini njalo, bese uthintana nenkampani yethu ngensizakalo yokuthengisa ngemuva kwecala lemibandela ekhethekile.

2. Hlanza ukotini we-PP njalo noma ubeke i-PP ukotini (ngokuvamile izinyanga ezi-4, isikhathi sokubuyiselwa singaqinisekile ngokuya ngekhwalithi ye-Water yamanzi ehlukile)

I-3. Ukufakwa kabusha okujwayelekile kwesisekelo se-carbon: izinyanga ezi-2 entwasahlobo nasekwindla, inyanga eyi-1 ehlobo it, izinyanga ezi-3 ebusika.

IV. Ukucaciswa kwesicelo

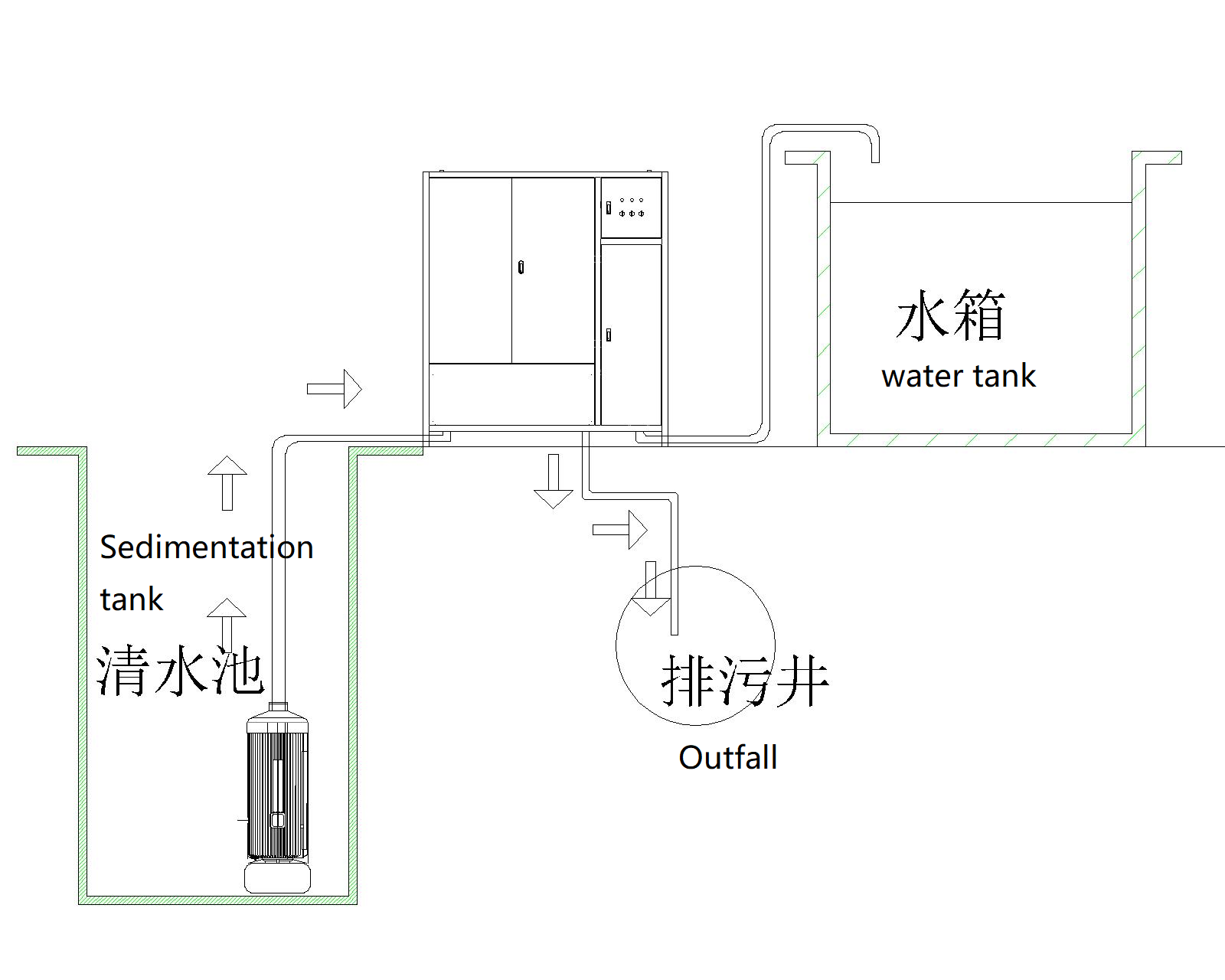

a) ukuhamba komsebenzi kwemishini

b) Ukudlula kwemali kwemishini

c) Izidingo zokuhlinzekwa kwamandla kwangaphandle

1

2. Abasebenzisi bakwamanye amazwe bangenza ngokwezifiso ngokuya ngokunikezwa kwamandla endawo.

d) Ukukhoma

1. Ngemuva kokuthi ukufakwa kwemishini sekuqediwe, yenza ukuzihlola, bese uqinisekisa ukufakwa okulungile kwemigqa namapayipi wesifunda ngaphambi kokwenza umsebenzi wokuqalisa.

2. Ngemuva kokuthi ukuhlolwa kwemishini sekuqediwe, ukusebenza kwecala kufanele kwenziwe ukuqhubekisela phambili ithangi lesihlabathi. Lapho inkomba yethangi le-sand tampleng iphuma, ukugcwala kwethangi lekhabhoni kwenziwa kuze kube yilapho inkomba ye-carbon tank iphuma.

3. Ngesikhathi, hlola ukuthi ngabe ikhwalithi yamanzi yokuhambisa indle ihlanzekile futhi ingenakungcola, futhi uma kukhona ukungcola, yenza imisebenzi engenhla kabili.

I-4. Ukusebenza okuzenzakalelayo kwemishini kungenziwa kuphela uma kungekho ukungcola esitolo sokuhambisa indle.

e) Iphutha elijwayelekile kanye nokuqeda izindlela

| Izindaba okuphikiswana ngazo | Isisusa | Isixazululo |

| Idivayisi ayiqali | Ukuphazamiseka kokuphakelwa kwamandla kwedivayisi | Bheka ukuthi ngabe ukuhanjiswa kwamandla okuphambili kuyamandla |

| Ukukhanya kwe-boot kuvuliwe, idivaysi ayiqali | Inkinobho yokuqala iphuliwe | Buyisela inkinobho yokuqala |

| Iphampu elingaphansi aliqali | Amanzi echibi | Ukugcwalisa ichibi lamanzi |

| Uhambo lwe-alamu yokuxhumana ne-Thermal | UMvikeli Wokutholwa Kokuzenzakalelayo | |

| Ukuntanta stack kulimele | Faka esikhundleni sokushintshana kokuntanta | |

| Amanzi kampompi awaziphindaphindeki | I-solenoid valve yonakele | Faka esikhundleni i-solenoid valve |

| I-Float Valve yonakele | Buyisela i-valve yokuntanta | |

| Igeyimu yokucindezela phambi kwethangi iphakanyisiwe ngaphandle kwamanzi | I-Blow-Down cutoff Solenoid valve yonakalisiwe | Faka esikhundleni se-drain solenoid valve |

| I-othomathikhi yokuhlunga ilimele | Faka esikhundleni i-othomathikhi yokuhlunga |